Product Details

Specifciation:

Speed bag:400times/H drums:200times/H

Height of Palletizer:200-1800mm

Stacking station 1、2、3(customzied)

Power : Total 8Kw,Running Power:6kW

Power Supply: AC 220V/380V,50Hz,

Air Source 0.5-06Mpa ~8m³/h/sets

Pneumatic component: AirTac

Electric component: Schneider/Chint

Photoelectric induction:Omron

Motor KUICHI

Material: Carbon steel baking paint(7035grey)

Size of Pallet: 1400mm*1600mm

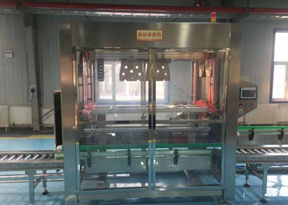

Product introduction:

This palletizer consists of: column host, guide rail, servo motor, leveling device, photoelectric switch, cylinder, deceleration motor, conveyor, control cabinet, pusher machine, discharge platform, palletizer gripper, protective fence and other parts;

working principle

The material products are transported by a conveyor and grasped by a positioning conveyor. The placement position is adjusted by an electrical control box and placed on a pallet. After the set number of layers is filled, the arm is turned to the other side for stacking. Wait for the forklift to cross the stacked rows and start a new round of stacking.

Characteristics of palletizer

1. Simple structure, stable operation, low failure rate (excluding human error), easy maintenance and repair;

2. Servo motor controls bag rotation, positioning, and smooth operation with high accuracy and low noise, solving the problem of vibration and impact

3. The touch screen enables human-machine dialogue, and all operations can be completed manually on the control cabinet screen, including setting and selecting stack types, making the operation very simple; The stacking style can be freely changed, with multiple stacking types to choose from: when the space occupied is less than 20 square meters, it can be stacked directly or in a five flower pattern, and can be adjusted freely;

4. The application of palletizing robotic arms is very flexible, and one machine can adapt to multiple types of products simultaneously. A fully automatic column palletizing machine can handle different products from two production lines at the same time. When updating the product, only new data needs to be entered and recalculated to start running, without the need for hardware or equipment modifications or settings;

5. The stacking type and stacking layers can be set arbitrarily, and the stacking type is neat, convenient for storage and transportation;

6. Stacking is high-speed and efficient, with adjustable speed, saving labor costs.

7. The host is highly integrated and installed as a whole, easy to install on site, and can be used by connecting to the discharge port

Related Suggestion

Online Consultation

———

First class quality service and professional after-sales team.

Factory address:Your company's full name

Office address:Your company's full name

Get in Touch

*We respect your confidentiality and all information are protected.

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.