Product Details

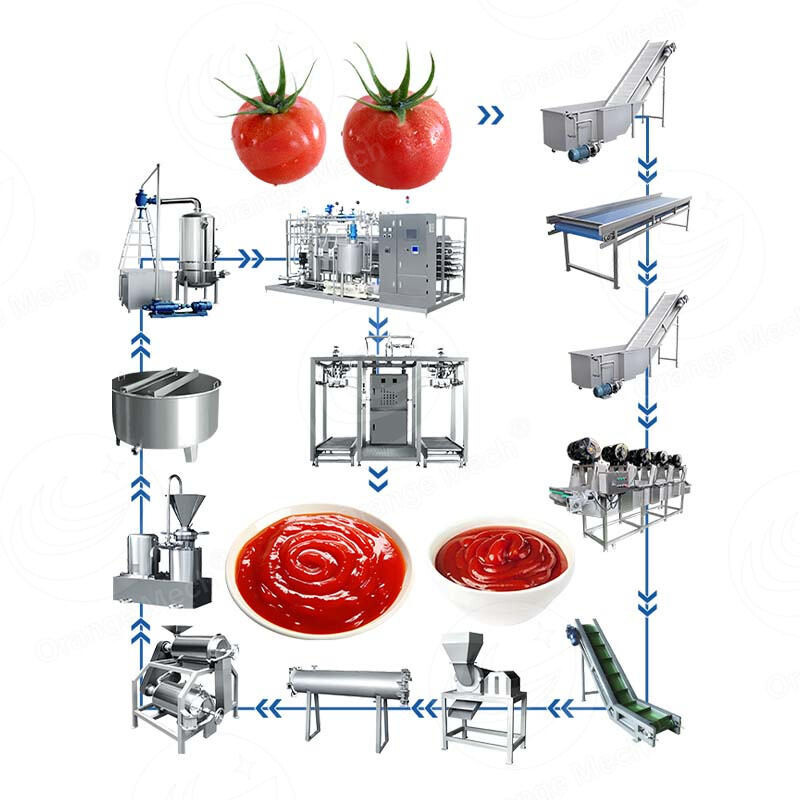

The jam production line is a complete industrial production process from fresh vegetables and fruits to sauce, involving multiple key links and equipment. Raw material preparation and cleaning: Select fresh and mature vegetables and fruits as the main raw materials, and use a cleaning machine to remove surface dirt and pesticide residues

Peeling and Seed Removal: After cleaning, vegetables and fruits are processed by a specific peeling and seed removal machine to remove the skin and internal seeds

Crushing: The crusher crushes vegetables and fruits and extracts fresh tomato juice, vegetables and fruits

Preheating enzyme inactivation: Vegetables and fruits need to be preheated before pulping to control the activity of pectinase and prevent juice separation in the product

Beating: After crushing the tomatoes, pour them into a blender, crush the flesh, remove the skin, and seed the seeds

Vacuum concentration: Vegetable and fruit pulp is concentrated by vacuum evaporation, usually using a three effect or four effect forced circulation tube evaporator

Blending and Standardization: According to taste requirements, add appropriate amounts of seasoning such as sugar and salt for blending

Filling: The concentrated vegetable and fruit sauce is filled using an automated filling machine to maintain strict aseptic conditions

Sterilization and Cooling: The filled vegetable and fruit sauce is sterilized using a high-temperature instantaneous sterilizer, and then rapidly cooled to ensure product quality and extend shelf life

Related Suggestion

Online Consultation

———

First class quality service and professional after-sales team.

Factory address:Your company's full name

Office address:Your company's full name

Get in Touch

*We respect your confidentiality and all information are protected.

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.