Product Details

"Introduction: The reverse osmosis pure water equipment adopts fully automatic control mode to reduce the impact of human error operation on the equipment belt. The design of a reduction system in the pretreatment system addresses the irreparable impact of excessive residual chlorine on the reverse osmosis membrane. The selection of reverse osmosis membrane adopts the original imported reverse osmosis membrane from the United States, with a service life of up to 3 years and a effluent conductivity of 1-10us. The pumps used are domestically produced Nanfang pumps and imported Grundfos pumps, which have low operating noise and long service life. We use Dow's professional design software, and the recovery rate can reach over 65%. High degree of automation, simple operation, stable water quality, and low operating costs. Main components: 1. Raw water tank: mainly solves the problem of unstable raw water pressure and reduces mechanical failures caused by frequent start-up or unstable raw water pressure of the lift pump during operation.

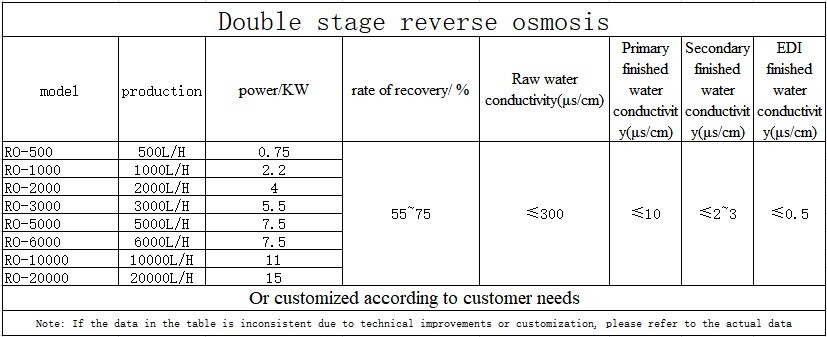

Double stage reverse osmosis:

Raw water (tap water, surface water, groundwater) is pressurized and sent to the pretreatment system for coarse filtration. After entering the filter for filtration, it is pressurized by a first stage high-pressure pump and sent to the first stage reverse osmosis system. The water produced by this system is then pressurized by a second stage high-pressure pump and sent to the second stage reverse osmosis system to produce product water, which is called two-stage reverse osmosis.

Double stage reverse osmosis is suitable for water with a conductivity greater than 500 μ s/cm, and the effluent conductivity is 1-10 μ s/cm.

"

Related Suggestion

Online Consultation

———

First class quality service and professional after-sales team.

Factory address:Your company's full name

Office address:Your company's full name

Get in Touch

*We respect your confidentiality and all information are protected.

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.