Intelligent packaging refers to the use of innovative thinking to incorporate new technologies such as mechanical, electrical, electronic, and chemical properties into packaging, enabling it to have both universal packaging functions and special properties to meet the specific requirements and environmental conditions of goods. Intelligent packaging is applied in almost all product application fields, including electronic products, food, beverages, pharmaceuticals, daily necessities, etc. According to Technavio's latest report, the global smart packaging market is expected to grow at a compound annual growth rate of nearly 8%, exceeding $31 billion by 2019. Intelligent packaging is increasingly becoming an extension of product functionality and a carrier for integrating various innovative technologies. The wave of high-tech has pushed packaging to a higher level of development, and intelligent packaging is about to become the next trend in the Internet of Things industry!

In recent years, with the advancement of materials science, modern control technology, computer technology, and artificial intelligence, the rapid development of intelligent packaging has been driven. The first generation of intelligent packaging technology is based on optical/visual recognition, focusing on solving anti-counterfeiting, tracking, anti-theft and other problems through optical characteristics. Its characteristic is to use only one technology; Unlike the first generation of intelligent packaging technology, the second generation of intelligent packaging technology will integrate printed electronics RFID、 New technologies such as flexible display make products and their packaging more approachable to humans, making human-machine interactive communication more convenient, and making "smart" packaging more proactive in presenting IoT characteristics.

According to IDTechEx's prediction, the global demand for electronic intelligent packaging equipment will rapidly increase to $1.45 billion within 10 years. The main service target of the electronic packaging market will still be consumer packaged goods (CPG) with electronic functions, and its total product quantity will increase to 14.5 billion pieces within 10 years. There are already a considerable number of mature application cases abroad, and corresponding industry organizations have been established to guide the development of the industry. However, the intelligent packaging industry in China is still in its infancy, and its demand for users and application environment is no less than that of foreign countries. In the next 2-3 years, the intelligent packaging market will become a new blue ocean for the Internet of Things industry. Intelligent packaging is divided into functional material intelligent packaging, structural intelligent packaging, and information-based intelligent packaging, which also involves preservation technology, water-soluble film packaging technology, QR code technology, packaging and structural innovation technology, portable packaging technology, texture anti-counterfeiting technology, magnetic resonance radio frequency anti-counterfeiting identification technology, food safety traceability solution technology, etc. In recent years, the increasingly popular printing electronic technology has applied traditional printing processes to the manufacturing of electronic components and products. Its major feature is that they do not rely on the conductor or semiconductor properties of the substrate material and can be deposited in thin film form onto any material. In the vast majority of intelligent packaging applications, more "intelligent" attributes can be achieved by integrating printing electronic technology, such as quality information recording and performance in warehousing, transportation, and sales processes, with advantages such as flexibility, environmental protection, and low cost.

The powerful functions of intelligent packaging in terms of protection, service, information, etc. make it increasingly widely used in fields such as pharmaceuticals, food, daily chemicals, logistics, etc. In addition to extending the shelf life of food, beverages, drugs, and other products, these smart packaging also bear the responsibility of improving product traceability.

(1) Intelligent food packaging: indicating whether the food has spoiled (TTI technology), extending the shelf life;

(2) Intelligent drug packaging: ensuring drug quality, improving accuracy and convenience of medication;

(3) Intelligent packaging for daily chemical products: cosmetics;

(4) Other intelligent packaging applications include inventory management, shopping orientation and interaction (in-depth product introduction), anti-counterfeiting and brand protection, quality and safety, preventing product repackaging, and adding new features.

Awesome! Share to:

Related Posts

- The Future of Automatic Filling Technology – Enhancing Efficiency and Reducing Waste

- Current Development Status of Lubricating Oil in China

- The Lubricant Professional Committee of the Petroleum Industry Chamber of Commerce of the All China Federation of Industry and Commerce has been officially established

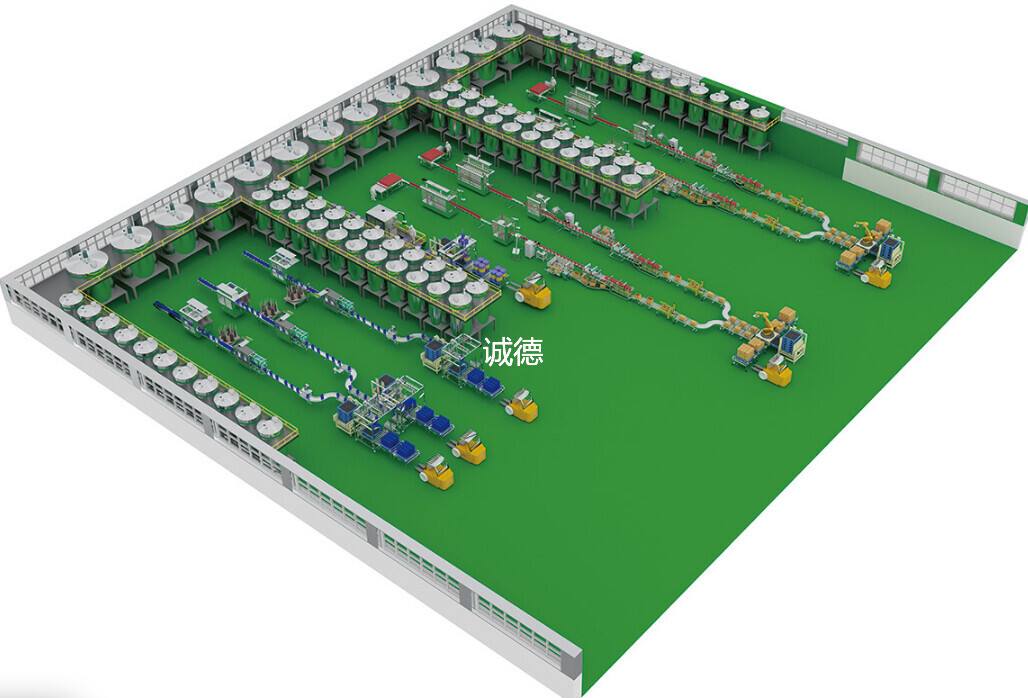

- EPCM Smart Factory

- The pesticide market is expected to improve by 2025

First class quality service and professional after-sales team.

Factory address:Your company's full name

Office address:Your company's full name

Get in Touch

*We respect your confidentiality and all information are protected.

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.