Product Details

Product Introduction:

The heated emulsion mixing tank is mainly suitable for mixing and stirring different materials, mixing and dissolving mucus, and uniformly mixing. It is an essential equipment in various industries, integrating functions such as variable frequency speed regulation wall scraping mixing, high shear homogenization emulsification, steam heating, cooling, electric control, temperature control, and operation platform. It is currently the ideal equipment for manufacturers to configure materials at home and abroad.

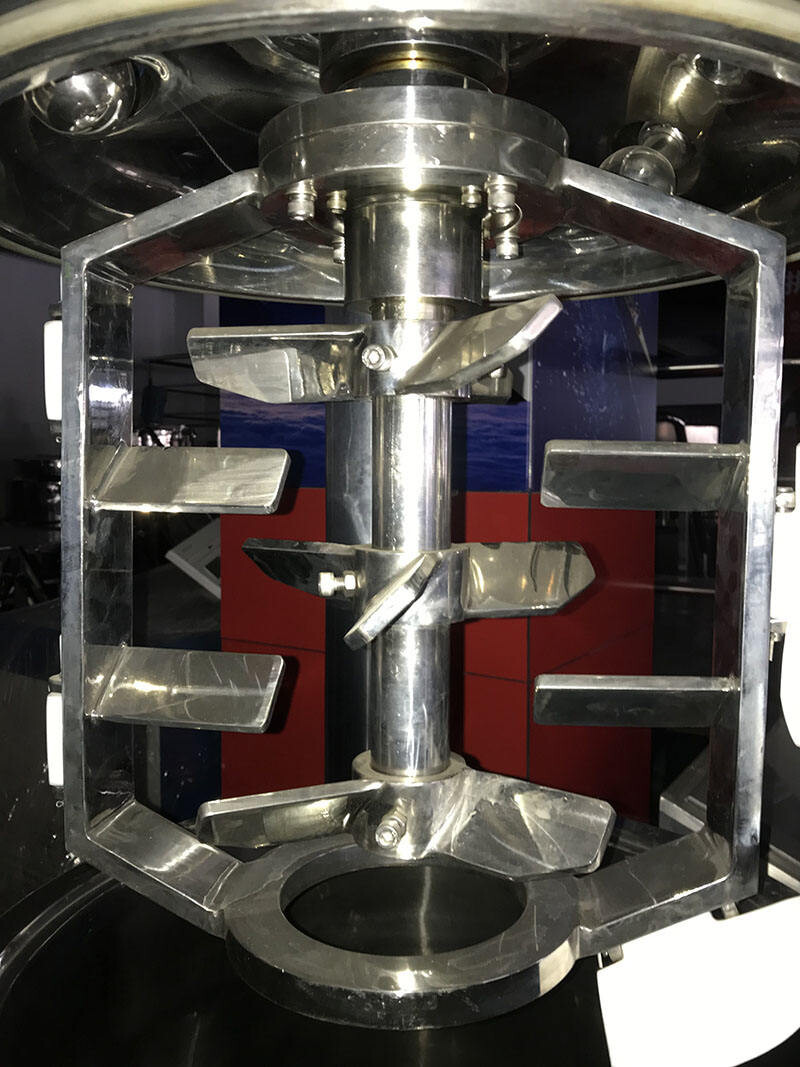

1. The all-round frame type scraping and stirring blade adopts frequency converter speed regulation to reduce the formation of bubbles when the temperature is low and the viscosity is high. We can produce high-quality products with different processes according to customer requirements.

2. The high-speed shear homogenizer mixes solid and liquid raw materials and other insoluble materials at a speed of 2880 revolutions per minute, saving energy and greatly shortening the production cycle.

3. Materials can be heated or cooled according to process requirements, and the heating method can be steam or electric heating according to customer requirements.

4. The pot body is composed of three layers of stainless steel plates welded together, and the tank body and pipes are mirror polished, fully complying with GMP requirements.

5. The material is imported SUS304 or SUS316L stainless steel, and the tank body and pipeline are mirror polished.

6. Optional vacuum pump for vacuum pumping (optional).

7. Optional bottom mounted dispersing head or FLUKO pipeline emulsifying head to accelerate material dissolution and emulsification.

8. The stainless steel electrical control cabinet can comprehensively monitor the operation of equipment and display data such as temperature, stirring speed, emulsification time, etc.

9. Easy to discharge, it can be directly discharged or equipped with a conveying pump for discharge.

10. The discharge port to the ground can be customized according to customer needs.

11. The main mixing adopts a variable frequency variable speed device, and the speed can be adjusted freely from 0-60 revolutions per minute.

12. The platform can be accessed from the front or side.

13. There are various forms of agitator blades that can be used for the production of different types of products; The blade can be selected from frame type scraping wall stirring blade, paddle type rowing blade stirring blade, propeller, three blade propulsion stirring blade or bidirectional stirring.

Related Suggestion

Online Consultation

———

First class quality service and professional after-sales team.

Factory address:Your company's full name

Office address:Your company's full name

Get in Touch

*We respect your confidentiality and all information are protected.

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.