The 200 liter (L) liquid filling machine has been in production for more than ten years and has achieved considerable success in the 200L filling industry. The 200 liter (L) liquid filling machine is mainly used in the chemical industry and has achieved great success, similar to well-known enterprises in the chemical and food industries, such as Changchun Chemical - mainly used for filling tree resin; Hangzhou Wahaha Group --- mainly filling essence liquid

All control components of our 200 liter (L) liquid filling machine are made of imported materials from foreign original factories, with reliable and durable quality. For example, the pneumatic ball valve is purchased from the DONGYU brand, and the control panel switch is made of Schneider from France. Especially for vulnerable parts, aluminum alloy material is used, and a 7-inch ultra large liquid crystal full Chinese display screen is used; The large explosion-proof box is rated EXD II BT5 and is made of cast aluminum. All electrical control components are placed inside the explosion-proof box to ensure reliable performance.

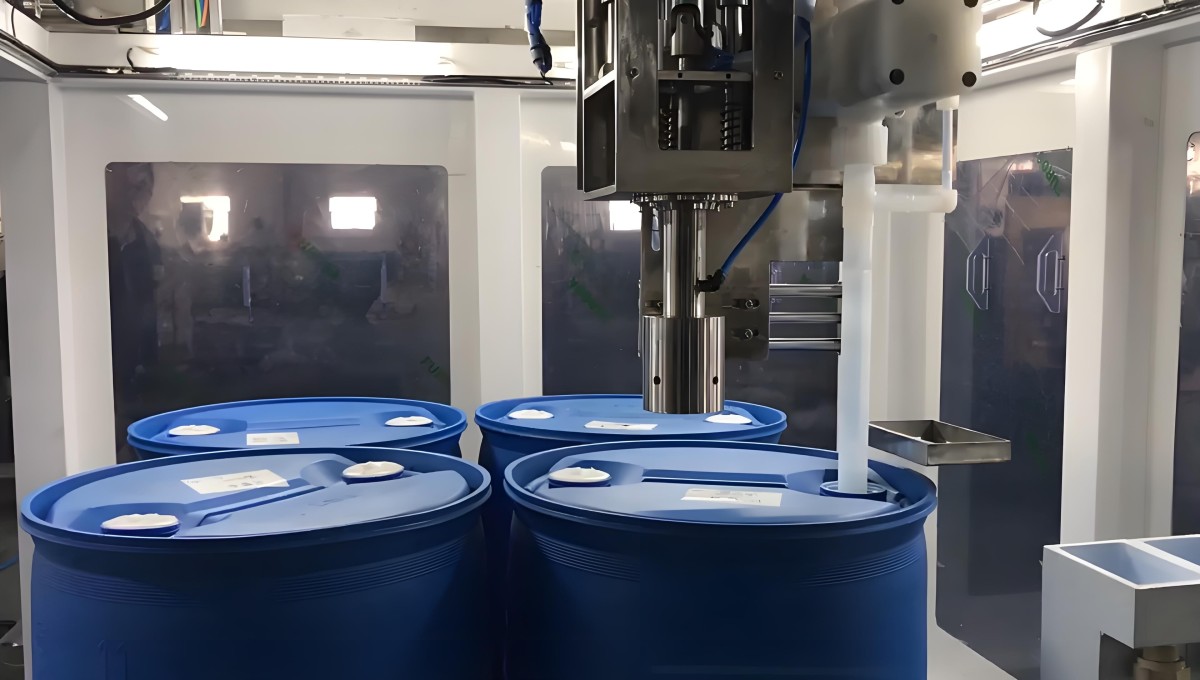

The intelligent 200 liter (L) liquid filling machine has finally been launched after continuous design and improvement by our R&D and design department.

Intelligent 200 liter (L) liquid filling machine product features:

Four barrel filling: Four barrels can be placed on the pallet at the same time, manually aligned with the barrel mouth and filled one by one, eliminating the trouble of stacking pallets after single barrel filling;

Explosion proof design: The entire system is manufactured according to explosion-proof standards;

Splash proof filling: The filling gun adopts an insertion type filling to avoid splashing materials on the barrel and affecting the outer packaging;

Accurate filling: The system adopts a three-stage automatic filling method for large, medium, and small materials to improve accuracy;

Net weight filling: Every time the filling is started, the system will automatically execute the weight deduction function to reset the weight on the weighing platform to zero;

Sequential filling: After the single barrel filling value is reached, the filling gun will automatically lift and wait for the next start;

Emergency stop: In case of an emergency, press the emergency stop button to terminate the filling process;

Anti mistake design: When the filling gun is not inserted into the barrel and is pushed out of the barrel mouth, the filling gun will automatically lift and not perform filling;

Leak proof design: Unique anti drip device to prevent materials from dripping onto the bucket;

Effortless design: After filling is completed, simply manually push the entire pallet out of the weighing platform;

One click operation: Adopting a one click operation method: start - filling gun descent - automatic peeling - start filling - complete filling gun lifting.

We will continuously update and improve the product functions in our future production, constantly improving production efficiency and operational stability. Providing excellent service to every customer is the pursuit of us at Zhongheng.

Welcome to visit our company for inspection. Our address is No.1 Jinrui Road, Xiangcheng District, Suzhou! Our website's: Liquid Filling Machine

Liquid filling machine is a device used in industries such as chemical, grain, etc. for automatic weighing and packaging of liquid materials. Adopting high-precision fully electronic weight weighing measurement to control the automatic quantitative filling and filling operation of raw material barrels, its automation level is high, which can avoid material overflow as much as possible, prevent material pollution to the environment, and effectively protect operators. At the same time, the system can be used in humid, dangerous or other adverse environments.

Awesome! Share to:

Related Posts

- The Future of Automatic Filling Technology – Enhancing Efficiency and Reducing Waste

- Current Development Status of Lubricating Oil in China

- The Lubricant Professional Committee of the Petroleum Industry Chamber of Commerce of the All China Federation of Industry and Commerce has been officially established

- EPCM Smart Factory

- The pesticide market is expected to improve by 2025

First class quality service and professional after-sales team.

Factory address:Your company's full name

Office address:Your company's full name

Get in Touch

*We respect your confidentiality and all information are protected.

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.